Uniforms that last and look good for a long time

At Olino, we bring over a decade of expertise in designing and supplying uniforms tailored to the aviation industry. With 90 airline clients worldwide, we’ve built a reputation for delivering professional, durable, and stylish uniforms that meet the unique demands of airline staff.

From long hours in the air to busy schedules on the ground, uniforms must be durable, comfortable, and professional. That’s why we prioritize high-quality materials and careful craftsmanship in every piece we create. Our uniforms are built to withstand the challenges of the aviation industry while maintaining their style and fit over time.

Why Chose Our Uniforms?

1. Durability Through Premium Fabrics

We select only the finest fabrics to ensure that our uniforms last. These materials are chosen for their strength, resistance to wear, and ability to maintain their shape and appearance after repeated use. Whether it’s a pilot's jacket or a cabin crew shirt, every garment is designed to endure the unique challenges of daily airline operations.

2. Long-lasting Performance

Our uniforms are tested for performance to ensure they maintain their professional look even after countless hours of service. With proper care, you can rely on your uniform to stay as polished and functional as the day you first wore it. You can rely on your uniform and keep focusing on your daily tasks.

3. Comfort Meets Quality

In addition to durability, our fabrics offer superior comfort. Lightweight, breathable, and easy to wear, our uniforms help keep airline staff comfortable and focused, no matter how long the flight.

4. High-quality fabric

The fabric has a high quality because it is carefully woven and has a good color fastness. We select fabric that keep up to our standards. Testing fabrics for consistency is a procedure we do all the time. The high-quality fabric also has a positive influence on the airlines signal value.

5. Production with minimum waist

During production of the uniforms, we make maximum use of the fabric to minimize waste. We save clippings for later use. If we have small production defects on garment, the clothes are being collected and sold at reduced price.

6. Built for flying – designed for you.

We fine-tune after user testing and continuously update the collections so that they are live up to today's style and requirements. We develop user-driven designs in close collaboration with users and incorporate the airlines values.

For Icelandair we designed their uniforms with the spirit of Iceland in mind and shaped for the crew by the crew.

7. Designed for everybody.

We are all different and our designs are developed to take this into account, by making the garments ready for adjustment to fit every kind of shape.

8. User test

When uniforms are developed or updated, we have users testing the garments in the correct environment. This is an import step in the development phase to be able to make the adjustment that is needed to ensure a uniform outfit that is durable. The feedback we get is of high value and the best we for us to make uniform garments that wearers require.

Caring for Your Uniform

A high-quality uniform deserves proper care. At Olino, we don’t just provide exceptional garments—we also encourage and advise uniform users on how to maintain their clothing to maximize its lifespan. By following our care guidelines, you can extend the durability and reduce the environmental impact, costs and keep your uniform looking its best for years to come.

Maintenance Tips for Long-Lasting Uniforms:

- Wash with Care: Always follow the care instructions provided with your uniform to prevent shrinkage or damage.

- Handle Stains Promptly: Address spills or stains immediately to avoid permanent marks.

- Store Properly: Use hangers and garment bags to maintain the shape and protect the fabric.

Changing look of current uniform garments

When changes are made for the corporate identity, and it will affect the look of the uniform,

you do not necessary need new garments.

The Pilots of Maersk Air Cargo went from golden ranking stripes to silver ranking stripes.

We changed the stripes on their jackets instead of making completely new jackets.

This way, both resources and money were saved.

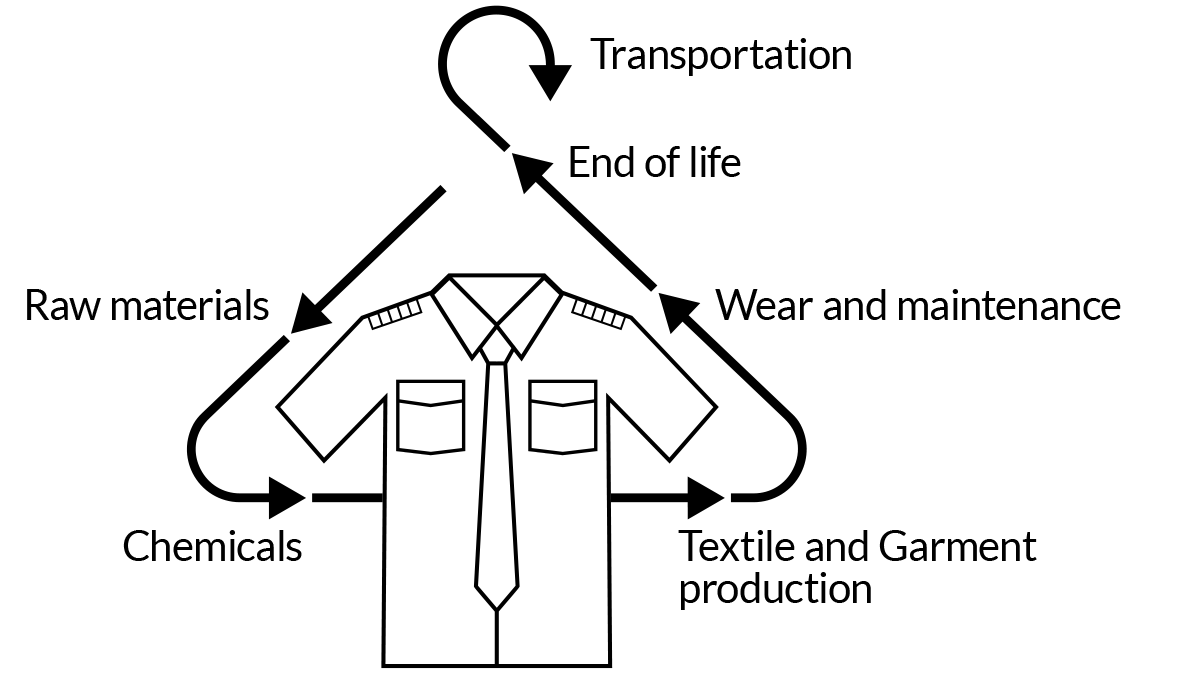

Reducing CO2 footprint

Our goal is to reduce CO2 footprint together with our clients. We are making an effort to reduce CO2 footprint into every step of the production. We are in the process of mapping our CO2 footprint and setting new goals.

Raw materials

The main material used for uniforms are wool, wool-polyester blends, cotton, cotton-polyester blends and polyester.

We are immersed in the development eco-friendly fibers and fabrics to offer you up to date solutions for your uniforms in collaboration with our industry partners, trade organizations and public funded projects.

Wool

Wool is the original renewable material for clothing. Wool is naturally hard-wearing and long-lasting, light weight and great for temperature regulation. It is easy to care for and is quite resistant to staining. No synthetic fiber can match the properties of wool.

Pure wool garments are easier to recycle than other garments. Wools market share of recycled fibers is already far greater than its total market share. Wool garments have long lifespans, meaning they are used or worn longer than other textile fiber products. During their lifetime, wool garments tend to get washed less frequently and at lower temperatures.

At the very end of its lifespan, wool biodegrades readily in months and poses no environmental hazards.

Pros:

- 100 % natural

- Biodegradable

- Wrinkle resistant

- Naturally elastic

- 100 % renewable

- Naturally breathable

- Thermal insulation ability

- Odor resistant

- Stain resistant

- Fire resistant

- Long lasting

Source: woolmark.com

Cons:

- Special washing and care

- No Tumble drying

- Tensile strength is weaker than other fibers

- More expensive than synthetic materials

- Degradable by sunlight

- Not moth proof

The disadvantages can be eliminated by mixing wool with e.g. polyester.

Virgin Polyester

Virgin polyester is a synthetic fiber created through a chemical reaction involving petroleum, and it’s the most common form of PET (polyethylene terephthalate).

So, basically, polyester is… plastic that you can wear!

A mix of Polyester and Wool result in strong and long-lasting fabrics, because the two materials complement one another well.

Pros:

- Affordable fabric

- Long lasting

- Strong and flexible

- Moisture resistant

- Easy to care for

- Dries quickly

- Resistant to wrinkles, shrinking and fading

- No cultivating land nor pesticides required

- Resistant to sunlight

- Weatherproof

- Stable in shape

- Good in combination with wool and complements what the wool lacks

Find more information about Polyester here: Textile Exchange

Cons:

- Requires high energy and water consumption

- Petroleum based

- Not biodegradable

- Releases microplastics whenever washed

- Less breathable

- Can generate static electricity

- Heat sensitive

- Odor retention

- Chemical Processing

- Less thermally insulating

- Poor absorption capacity

- Attracts dirt and grime

Recycled Polyester - pros and cons

Recycled polyester known as rPET is made by melting down existing plastic and re-spinning it into new polyester fibers.

According to the Danish Ministry of the Environment, 99 percent of all recycled polyester comes from plastic bottles and not from discarded clothing.

Source: plastikviden.dk

The Pros:

Recycled polyester is keeping plastic from going to landfill and the ocean and gives a second life to a material that’s not biodegradable.

It takes less resources to make recycled polyester compared to virgin polyester – it requires 59 percent less energy that virgin polyester.

Source: weavabel.com

The Cons:

Recycled polyester is an oil-based material, end products are only recycled to a limited degree, and it cannot be recycled repeatedly.

Many garments are not made from recycled polyester alone, but a blend of recycled polyester and other materials. In that case, it is difficult/impossible to recycle the fabric.

When plastic bottles are recycled to recycled polyester, the plastic bottles are removed from their own circular ecosystem. It is good to support the collection and recycling of PET bottles, but if the product that the bottles are converted into has a short lifespan and cannot be recycled afterwards, then we simply end up with a different type of plastic waste than PET bottles.

Recycled polyester releases microplastics when you wash the garments in your washing machine, and they end up in the ocean/environment.

What kind of recycled polyester does Olino use for the garments?

For our Tech Coats we use recycled polyester made of PET, which is the fabric that is currently available for Tech Coats. To improve we and our subcontractors continuously follow the development of recycled polyester and the results that researchers come up with.

Cotton

Cotton is made from the natural fibers of the cotton plant, specifically from the seed hairs of the cotton boll, which is the protective capsule around the seeds of the plant.

Cotton is valued for being soft, breathable, and biodegradable, which makes it one of the most widely used natural fibers in the world.

Here’s a quick breakdown of the process:

Plant: Cotton comes from the cotton plant, a shrub mostly grown in warm climates.

Boll: After the plant flowers, it forms a cotton boll filled with soft, fluffy fibers.

Harvesting: These bolls are picked (either by hand or machine).

Ginning: The fibers are separated from the seeds in a process called ginning.

Spinning: The raw cotton fibers are then spun into yarn or thread.

Weaving or knitting: The yarn is woven or knitted to make cotton fabric, which is then used to make clothes and other textiles.

The length of seed fibers can be different – 10 to 60 mm. The longer the fibers, the higher the quality of the cotton.

The Pros:

- Cotton allows air to circulate, keeping the body cool.

- Feels soft against the skin, making it ideal for everyday wear.

- Less likely to cause skin irritation or allergic reactions.

- A great choice for sensitive skin or baby clothing.

- Absorbs moisture well, which helps with sweat.

- Often used in towels, undergarments, and summer clothing.

- Cotton is a renewable resource and breaks down more easily than synthetic fabrics.

- Strong fibers that can last through many washes if maintained well.

Find more information about Cotton here: Textile Exchange

The Cons:

- Cotton tends to crease and wrinkle, especially if it's 100% cotton. Can be eliminated by anti-wrinkle treatment.

- Can shrink when washed and dried at high temperatures, especially if not pre-shrunk.

- Colors may fade with repeated washing or sun exposure.

- While it absorbs moisture, it doesn’t dry quickly, which can leave you feeling damp.

- Cotton retains water and becomes heavy when soaked, making it less suitable for performance or athletic wear.

- Traditional cotton farming uses a lot of water and pesticides. However, organic cotton is a more sustainable option.

Viscose - Modal - Lyocell

Viscose is made from wood or other plants, that has been converted into textile fibers using a chemical process.

More specific viscose is made of cellulose from plant material such as beech, spruce, pine, eucalyptus, bamboo or other cellulose-containing material.

The wood fibers are broken down and dissolved using chemicals until a viscous wood pulp solution called "viscose" is formed. The pulp is then pressed through fine nozzles to form thin strands of regenerated cellulose, which are then spun into yarn that is woven or knitted into fabric.

Because viscose is based on a natural raw material, it differs from purely synthetic fibers.

However, the manufacturing process means that it is not a “natural” fiber in the same way as wool or cotton.

The Pros:

• Inexpensive

• Feels like silk

• Drapes beautifully

• Breathable

• Blends well with other fibers

• Dyes easily and produces beautiful, vivid colors

• Incredibly soft

• Lightweight

• Colorfast

• Easy to iron

Find more information about viscose here: Textile Exchange

The Cons:

• Tends to wrinkle – Can be eliminated by anti-wrinkle treatment

• Shrink in hot water – Remember to check the care label. To avoid shrinking use dry-cleaning or wash in cold water.

• Impact on the environment due to the chemicals used. Lyocell have a less impact on the environment than regular viscose

• Needs to be dry cleaned most of the time

• Prone to stretching and does often not recover

• Weak, and even weaker when wet

• Absorbs moisture, body oils, and water, which may result in spots

• Spot treating can lead to permanent marking

A mix of viscose and ex. polyester can eliminate some of the disadvantages of viscose.

Modal

Modal is related to viscose, but with slightly different characteristics.

Modal is a modified viscose with higher wet strength than regular viscose. Modal has up to 15% elongation at break and is suitable for blending with polyester and cotton.

Modal compared to regular viscose:

• Better strength

• Better wet strength

• Wrinkle less

• Better elasticity

Lyocell

Lyocell is also made of cellulose fiber, but more environmentally friendly.

The production takes place by dissolving the cellulose fibers in an aqueous solution of oxides and spinning the fibers in a solvent bath. The production takes place by dissolving the cellulose fibers in an aqueous solution of oxides and spinning the fibers in a solvent bath. Up to 99% of the chemicals are recycled - it is claimed.

Compared to regular viscose Lyocell have the following benefits:

• Less environmental impact

• Better dry and wet strength

• Better hand feel

• More silky shine

• Less shrinking

• Possibility of "peach skin" effect

Link: Textile Exchange